Introduction to Simmons 4-Inch Well Seal with Maintenance Port

A well seal is a key part of any water well system. It helps keep the well safe and clean. A well seal covers the top of the well casing and blocks dirt, bugs, and other harmful things from getting into the water. This keeps the water safe to use.

The Simmons 4-inch well seal with maintenance port is a trusted product used in many water wells. It is made to fit 4-inch well casings and works well for both residential and commercial wells. The Simmons brand is known for making strong and reliable well parts. One great feature of this well seal is the maintenance port. This small opening makes it easier to check and care for the well without removing the seal. It helps save time and keeps the well running smoothly.

This seal is built with tough materials that can last for many years. Its design helps it fit tightly on the well casing. The Simmons 4-inch well seal protects the water supply and gives peace of mind to well owners.

Understanding the Purpose and Function of Well Seals

A well seal is an important part of a water well system. Its main job is to keep the well safe and clean. The seal covers the top of the well casing and blocks harmful things like dirt, insects, and chemicals from getting into the well. This helps keep the water pure and safe to drink. Without a well seal, the well could easily become dirty and unsafe.

The Simmons 4-inch well seal with maintenance port is designed to protect the well while allowing easy access for check-ups and small repairs. The maintenance port is a small opening that lets you inspect the well without removing the entire seal. This makes it easier to take care of the well and helps prevent bigger problems.

Keeping the well sealed also protects the pump and other parts inside the well. It stops water from leaking out and keeps pressure balanced. A strong, well-fitted seal like the Simmons 4-inch model helps the whole water system work better and last longer.

Maintaining the well seal is very important. A damaged or loose seal can let in bacteria and other harmful materials, leading to dirty water. Regular checks and proper maintenance using the Simmons 4-inch well seal with maintenance port help keep the water clean and the system safe.

Key Features of the Simmons 4-Inch Well Seal

The Simmons 4-inch well seal with maintenance port is designed to offer both durability and ease of use. It has many important features that make it a top choice for protecting water wells.

Durable Construction Materials

The Simmons 4-inch well seal is built with high-quality materials. It often uses cast iron, steel, and ABS plastic. These materials are strong and resist rust, corrosion, and wear. This means the seal can last for many years, even in harsh weather or underground conditions. The solid build keeps the well secure and helps protect the water supply.

Smart and Flexible Design

The Simmons well seal is designed for both strength and flexibility. It comes with either a split top plate or a solid top plate.

- The split top plate makes installation easier because it can fit around pipes without needing to disconnect them.

- The solid top plate gives a tighter, more secure seal for added protection.

This well seal also works with different drop pipe sizes. It can easily fit common pipe sizes, making it perfect for many types of well systems.

Integrated Maintenance Port for Easy Access

One of the best features of the Simmons 4-inch well seal is the built-in maintenance port. This small opening allows for quick inspections and minor repairs without removing the seal. You can check pressure, add chemicals, or inspect the system easily through the port. This feature saves time and effort while helping to keep the well system in good shape.

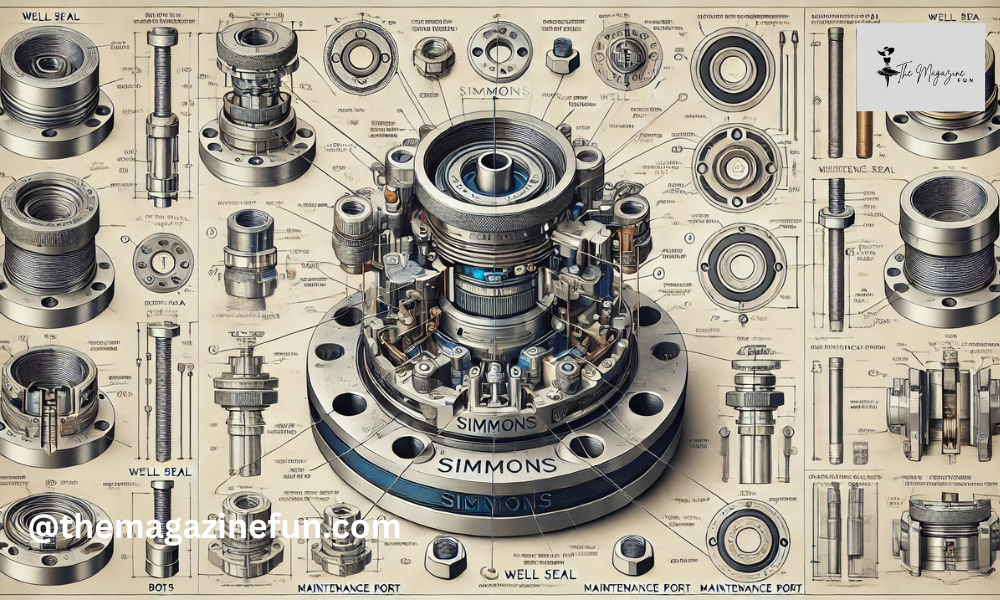

Detailed Diagram Analysis

Understanding the parts of the Simmons 4-inch well seal with maintenance port helps explain how it works to protect a well system. Each component is designed to keep the well secure and maintain water quality.

Visual Representation of the Simmons 4-Inch Well Seal with Maintenance Port

The diagram of the Simmons 4-inch well seal shows a clear view of all its parts. It highlights how the pieces fit together to create a tight seal on the well casing. The diagram includes labeled parts such as the upper plate, lower plate, gaskets, bolts, and the maintenance port. This layout makes it easier to understand how the seal functions and how to install or maintain it properly.

Identification of Components

- Upper Plate:

- This is the top section of the seal. It can be either a split top plate or a solid top plate.

- The upper plate holds the drop pipe and covers the casing, blocking contaminants.

Lower Plate:

- The lower plate sits inside the casing and works with the upper plate to create a strong, leak-proof seal.

Gaskets:

- Rubber or neoprene gaskets are placed between the plates.

- They provide a tight seal to prevent leaks and block out dirt, insects, and water from outside.

Bolts and Nuts:

- Bolts hold the upper and lower plates together.

- Tightening the bolts compresses the gaskets, making the seal stronger and more secure.

Maintenance Port:

This is a small, built-in opening on the upper plate.

It allows easy access to the well for pressure checks, adding chemicals, or small inspections without removing the seal.

Explanation of How Each Part Contributes to Overall Functionality

- The upper and lower plates work together to clamp tightly onto the well casing, forming the main barrier against outside contamination.

- The gaskets create a soft but firm layer that seals gaps between the plates and the casing, stopping leaks.

- Bolts and nuts secure the entire seal, ensuring the plates and gaskets stay tight and effective.

- The maintenance port provides easy access for quick maintenance, reducing the need to fully remove the seal.

Each of these parts plays a critical role in keeping the well system safe and working properly. The Simmons 4-inch well seal with maintenance port is designed to make well maintenance simple while offering strong protection.

Installation Guidelines

Proper installation of the Simmons 4-inch well seal with maintenance port is essential for keeping the well safe and functioning efficiently. Following the correct steps ensures a secure fit and long-lasting performance.

Step-by-Step Instructions for Proper Installation

Prepare the Well Casing and Seal Components

- Clean the top of the well casing to remove dirt, debris, and rust.

- Inspect the Simmons 4-inch well seal for any damage or missing parts. Ensure all components (upper plate, lower plate, gaskets, bolts, and maintenance port) are ready.

Position the Lower Plate

- Slide the lower plate into the well casing.

- Center it properly to ensure even sealing.

Insert the Drop Pipe

- Insert the pump drop pipe through the upper plate and gasket opening.

- Adjust the pipe so it fits securely and does not press against the casing.

Align the Upper Plate

- Place the upper plate over the well casing, aligning it with the lower plate.

- If using a split top plate, carefully position both halves around the drop pipe before securing.

Tighten the Bolts and Nuts

- Evenly tighten the bolts around the seal using a wrench.

- Tighten in a crisscross pattern to evenly compress the gaskets and create a tight seal.

Check the Maintenance Port

- Ensure the maintenance port cap is properly closed.

- The port should be sealed to prevent contaminants from entering.

Final Inspection

- Check for gaps or loose fittings.

- Make sure all parts are secure and the seal is firm around the casing.

Common Pitfalls to Avoid During Installation

Overtightening Bolts:

- Over-tightening can crush the gaskets, causing leaks. Tighten bolts evenly and moderately.

Misaligned Plates:

- If the upper and lower plates are not aligned, the seal won’t be tight. Double-check alignment before tightening.

Damaged or Dirty Gaskets:

- Dirty or damaged gaskets can’t create a proper seal. Always clean or replace worn gaskets.

Ignoring the Maintenance Port:

- Leaving the maintenance port open or loose can allow dirt and water into the well. Always secure the cap.

Importance of Following Manufacturer Specifications

The Simmons 4-inch well seal with maintenance port is designed for specific well sizes and conditions. Following the manufacturer’s instructions ensures the seal works correctly and lasts longer. Using the wrong tools, over-tightening, or skipping steps can lead to leaks and system damage.

Maintenance Procedures

Proper maintenance of the Simmons 4-inch well seal with maintenance port is essential for keeping your water well system safe and efficient. Regular inspections and timely repairs can prevent bigger problems and extend the life of the well seal.

Regular Inspection Routines to Ensure Optimal Performance

Monthly Visual Checks:

- Inspect the well seal monthly for any visible damage. Look for cracks, rust, or loose bolts on the upper and lower plates.

Gasket Inspection (Every 6 Months):

- Check the gaskets for signs of wear, such as cracks, dryness, or flattening. Damaged gaskets can cause leaks and reduce the seal’s effectiveness.

Bolt Tightness (Quarterly):

- Ensure all bolts are securely tightened. Use a wrench to check for any loose bolts that may need tightening. Avoid over-tightening to protect the gaskets.

Seal Surface Cleaning (Every 6 Months):

- Clean the surface of the well seal to remove dirt, debris, or corrosion. This helps prevent buildup that can damage the seal.

Utilizing the Maintenance Port for Inspections and Minor Repairs

The built-in maintenance port makes routine check-ups and small repairs easy:

Water Level Checks:

- Open the maintenance port to check the water level in the well without removing the entire seal.

Pressure Testing:

- Use the port to test the pressure inside the well casing, ensuring the system is balanced and working properly.

Chemical Treatments:

- Introduce cleaning or treatment solutions through the maintenance port to disinfect the well or manage bacterial growth.

Ventilation Inspection:

- Ensure the port is clear and properly sealed when not in use. This prevents air or contaminants from entering the well.

Signs of Wear and Tear: When to Replace Components

Cracked or Worn Gaskets:

- Gaskets should be replaced if they show signs of cracking, hardening, or flattening. A damaged gasket can lead to leaks and contamination.

Corroded Plates or Bolts:

- Rust on the upper or lower plates or bolts weakens the seal. Replace any rusty or corroded parts to maintain strength.

Loose or Damaged Maintenance Port Cap:

- If the maintenance port cap is loose, cracked, or missing, it must be replaced to prevent contaminants from entering the well.

Water Leaks Around the Seal:

- Any visible water leakage is a clear sign that the seal is failing. Inspect all parts and replace damaged components immediately.

Troubleshooting Common Issues

Even with proper installation and maintenance, issues can sometimes occur with the Simmons 4-inch well seal with maintenance port. Identifying and fixing problems early can prevent bigger issues and protect your water well system.

Identifying and Resolving Leaks or Seal Failures

Leak Detection:

- Check for water pooling around the well seal or damp areas on the casing. This could indicate a loose seal or damaged gasket.

Loose Bolts:

- If bolts are loose, carefully tighten them in a crisscross pattern. Avoid over-tightening, which can crush the gasket.

Damaged Gaskets:

- If leaks continue, inspect the gasket for cracks, tears, or flattening. Replace worn-out gaskets with new ones that fit the Simmons 4-inch well seal.

Misaligned Plates:

- Ensure the upper and lower plates are properly aligned. Misalignment can create gaps, leading to leaks. Adjust and re-tighten the bolts if needed.

Addressing Corrosion or Material Degradation

Rust on Metal Parts:

- If you notice rust on the bolts, plates, or maintenance port, clean the affected area with a wire brush. Apply a rust-resistant coating to prevent further damage.

Cracked or Warped Plates:

- Replace any cracked or bent plates. Damaged plates cannot seal properly and can cause leaks.

Worn Maintenance Port Cap:

- If the maintenance port cap is corroded or damaged, replace it immediately to keep contaminants out. A secure port cap is vital for maintaining water quality.

Ensuring Proper Ventilation and Pressure Balance

Clogged Vent Holes:

- Some well seals have vent holes to balance air pressure. Check for blockages in these vents. Clean them if they are clogged with dirt or debris.

Pressure Build-Up:

- If the system feels pressurized or air escapes when opening the maintenance port, the system might not be properly vented. Use the port to release trapped air carefully.

Loose Maintenance Port Cap:

- A loose or missing cap can cause air leaks, disturbing the pressure balance. Always ensure the port cap is tightly sealed.

Enhancing Water Quality and System Longevity

The Simmons 4-inch well seal with maintenance port plays a key role in keeping your water clean and your well system running smoothly. A properly installed and maintained well seal protects against harmful contaminants, supports a sanitary environment, and extends the life of your well system.

Role of the Well Seal in Protecting Against External Contaminants

Barrier Against Contamination:

- The well seal creates a tight barrier that prevents dirt, insects, chemicals, and other harmful materials from entering the well. This protects the water from becoming dirty or unsafe to use.

Protection from Surface Water:

- Heavy rain or flooding can cause surface water to enter the well if it’s not sealed correctly. The Simmons 4-inch well seal stops this water from leaking into the well, keeping it safe from bacteria and chemicals.

Sealed Maintenance Port:

- The built-in maintenance port allows for inspections and treatments without opening the entire well, reducing the risk of contamination during maintenance.

Best Practices for Maintaining a Sanitary Well Environment

Routine Inspections:

- Regularly inspect the well seal, casing, and surrounding area for damage, leaks, or cracks. This helps catch small problems before they grow.

Keep the Wellhead Clean:

- Clear away leaves, dirt, and debris from around the well. Do not allow chemicals or fertilizers near the well area.

Check the Maintenance Port Cap:

- Always make sure the maintenance port is tightly closed to prevent contaminants from entering.

Annual Well Testing:

- Test your well water every year for bacteria, nitrates, and other pollutants to ensure it’s safe to drink.

Seal Inspection After Weather Events:

- Inspect the well seal after storms or flooding to make sure it hasn’t been damaged.

Impact of Proper Sealing on the Lifespan of the Well System

Prevents Early System Wear:

- A properly sealed well stops dirt and water from damaging the pump, pipes, and electrical parts. This prevents breakdowns and costly repairs.

Reduces Corrosion and Rust:

- By blocking moisture, the well seal reduces rust and corrosion on metal parts, helping the system last longer.

Keeps Pressure Balanced:

- A tight seal maintains proper pressure inside the well, allowing the pump and other components to work efficiently without strain.

Lowers Maintenance Costs:

- Fewer leaks and less damage mean fewer repairs and lower costs over time.

Customization and Compatibility Considerations

The Simmons 4-inch well seal with maintenance port is designed to meet the needs of different well systems. Its flexible design allows it to fit various setups and applications. Understanding its customization options and compatibility ensures you choose the right seal for your well system.

Options for Different Well Casing Sizes and Configurations

Multiple Casing Sizes:

- Although designed for 4-inch well casings, Simmons also manufactures well seals for other casing sizes, such as 2-inch, 6-inch, and larger diameters. This makes it easier to find the right fit for your specific well system.

Split and Solid Top Plates:

- The split top plate design allows easy installation without removing existing pipes, ideal for systems that need quick adjustments.

The solid top plate design offers a tighter seal for wells where maximum protection is needed.

Adaptable Drop Pipe Openings:

- The well seal can accommodate different drop pipe sizes and materials, including PVC, steel, and galvanized pipes. This ensures a snug fit and reduces the risk of leaks.

Compatibility with Various Pump and Piping Systems

Submersible and Jet Pumps:

- The Simmons 4-inch well seal works well with both submersible pumps and jet pumps. It provides a secure fit around the pump drop pipe, preventing leaks and contamination.

Multiple Pipe Materials:

- The seal is compatible with various piping materials such as PVC, steel, and galvanized pipes. This makes it a versatile choice for different well systems.

Pressure Tank Systems:

- The well seal works efficiently with pressure tanks by maintaining proper air pressure balance and reducing system strain.

Availability of Custom Well Seals for Specific Applications

Custom Seals for Unique Systems:

- Simmons offers custom well seals for specialized well setups. Custom options can include different plate designs, gasket materials, and special port configurations to fit unique systems.

Special Coatings and Materials:

- Custom well seals may feature coatings that resist corrosion in wells exposed to salty or acidic water, extending the product’s life.

Custom Maintenance Ports:

- For specific maintenance needs, custom seals can include larger or extra maintenance ports for easier access and system monitoring.

Conclusion

The Simmons 4-inch well seal with maintenance port is an essential part of any well system. It offers strong protection against contamination, helps maintain water quality, and supports the overall efficiency of the well. Its durable design, tight seal, and built-in maintenance port make it a reliable choice for both residential and commercial wells.

Proper installation and regular maintenance are key to getting the best performance from the Simmons well seal. Following the correct installation steps, inspecting the seal regularly, and using the maintenance port for quick checks can prevent leaks, contamination, and costly repairs. Replacing worn parts on time and keeping the well area clean will also extend the life of the well system.

FAQs About the Simmons 4-Inch Well Seal with Maintenance Port

What is the purpose of the maintenance port on the Simmons 4-inch well seal?

The maintenance port allows for easy access to the well for inspections, pressure checks, and minor repairs without removing the entire seal. It helps maintain the well system efficiently and safely.

How often should I inspect the Simmons 4-inch well seal?

It is recommended to inspect the well seal every 3 to 6 months. Regular checks help detect early signs of wear, leaks, or damage, ensuring the seal remains effective.

Can I install the Simmons 4-inch well seal myself?

Yes, the Simmons 4-inch well seal is designed for easy installation. However, it’s important to carefully follow the manufacturer’s instructions to ensure a proper and secure fit.

How do I know if the well seal needs to be replaced?

Signs that the seal may need replacement include visible cracks, leaks, loose bolts, or worn-out gaskets. Regular maintenance can help catch these issues early.

Is the Simmons 4-inch well seal compatible with all types of pumps?

Yes, it is compatible with most submersible and jet pumps. It also works with various drop pipe materials like PVC, steel, and galvanized pipes.

Thank you for reading my article. If you want to read more articles like this, please visit my website The Magazine Fun.